Page 7 - James Nicholson

P. 7

CLIMATE NEUTRAL CATALOGUE

CERTIFIED CLIMATE PROTECTION

We assume responsibility With every sheet of recycled paper

for our climate. we improve our ecological footprint

This means that by supporting an international climate Recycled paper protects forests, biodiversity and the climate

protection project by climatePartner, we compensate for and saves energy, water and CO 2 during production. For producing

the inevitable CO 2 -emissions resulting from the printing our this year’s main catalogue, we are using 100% FSC certified

of our catalogues. recycled paper.

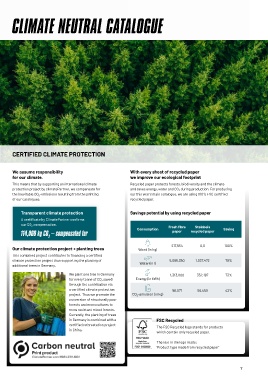

Transparent climate protection Savings potential by using recycled paper

A certificate by ClimatePartner confirms

our CO 2 compensation. Fresh fibre Steinbeis

Consumption paper recycled paper Saving

114,000 kg CO – compensated for

2

Our climate protection project + planting trees Wood (in kg) 217,554 0,0 100%

This combined project contributes to financing a certified

climate protection project thus supporting the planting of 5,085,350 1,037,472 79%

additional trees in Germany. Water (in l)

We plant one tree in Germany 1,313,000 352,187 73%

for every tonne of CO 2 saved Energy (in kWh)

through the contribution via

a certified climate protection 98,071 56,459 42%

project. Thus we promote the CO 2 -emission (in kg)

conversion of structurally poor

forests and monocultures to

more resistant mixed forests.

Currently, the planting of trees

in Germany is combined with a FSC Recycled

certified reforestation project The FSC Recycled logo stands for products

in China. which contain only recycled paper.

The text in the logo reads:

‘Product type made from recycled paper’

7